Mops are essential cleaning tools in both household and industrial settings. To ensure they perform efficiently over time, it’s important to simulate their real-world use and test their cleaning capabilities. محاكاة استخدام الممسحة is a key method for assessing a mop’s durability, cleaning performance, and overall effectiveness. This article explores how اختبار ضمان جودة الممسحة, including the use of cleaning efficacy testers and other quality control methods, helps enhance mop performance and user satisfaction.

Mop Quality Assurance Testing: Key to Optimal Cleaning Performance

The goal of اختبار ضمان جودة الممسحة is to verify that mops meet the necessary standards for durability, cleaning efficiency, and safety. This process is crucial for manufacturers looking to deliver high-quality cleaning products to consumers. Quality assurance involves several tests that simulate the conditions mops will face during actual use. These tests ensure that mops maintain their cleaning ability over time, resist wear and tear, and can handle different surfaces and environments.

For example, cotton mop quality control includes testing the durability of cotton mops under various conditions, such as repeated use, exposure to cleaning solutions, and friction with different floor surfaces. These tests help assess whether the mop’s materials can withstand these factors without degrading.

One of the main tests for mop quality assurance is simulating the actual cleaning motions—sweeping and scrubbing—that a mop undergoes during typical usage. By simulating these movements, manufacturers can determine how well a mop performs in real-world conditions.

Cleaning Efficacy Tester: A Critical Tool for Mop Performance Evaluation

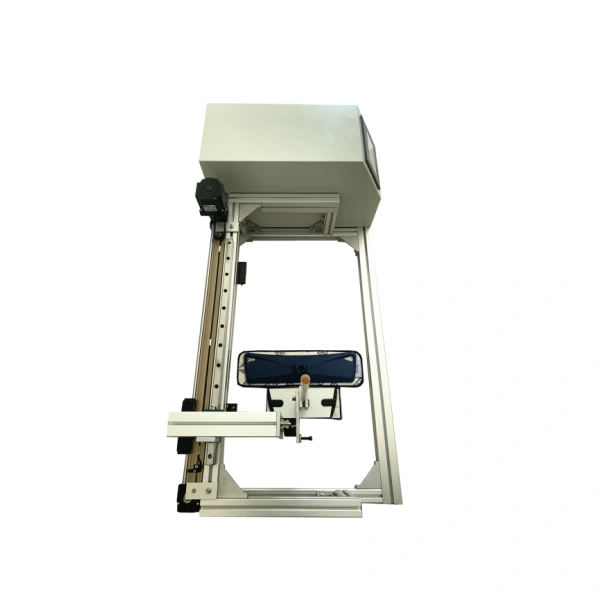

ال cleaning efficacy tester is designed to evaluate how well mops remove dirt, dust, and stains. This tester mimics the conditions mops will face when cleaning various surfaces. It’s an essential tool for determining whether a mop can meet the cleaning standards set by manufacturers and consumers alike.

Mops need to demonstrate good absorbency and cleaning power. A cleaning efficacy tester can simulate cleaning tasks such as absorbing liquid, removing stains, and ensuring that no residues are left behind after use. This tool helps manufacturers fine-tune their mop designs and materials to improve their overall cleaning performance.

Using a cleaning efficacy tester, manufacturers can assess factors like:

- Absorbency: How quickly a mop can absorb liquid and prevent spills from spreading.

- Stain removal: The ability to effectively clean stains without leaving traces behind.

- Durability: How well the mop holds up after repeated use in different cleaning scenarios.

By using a cleaning efficacy tester, manufacturers ensure that their mops are not only durable but also effective at performing their primary function: cleaning.

Mop Lab Quality Control: Ensuring Consistency Across Production

In addition to individual performance tests, mop lab quality control plays a crucial role in ensuring consistency across production. During production, multiple batches of mops are created, and it’s vital to ensure that each batch meets the same high standards.

Mop lab quality control includes testing the frictional properties of mop heads and handles, checking for defects, and ensuring that the material used in the mop head performs as expected. Testing for friction (as measured with tools like the cleaning efficacy tester) ensures that the mop provides the right balance of resistance during cleaning tasks, which can affect both cleaning efficiency and ease of use.

For cotton mops, cotton mop quality control specifically looks at the fiber quality, the weave of the mop, and its durability under stress. Over time, cotton fibers can break down or become less effective at absorbing liquids, which is why quality control ensures that mops maintain their performance even after repeated use.

Simulating Mop Use with Technology

ال mop use simulation process helps manufacturers evaluate how mops will behave under real-world conditions. By using simulated environments that replicate various cleaning surfaces—such as tiles, wood floors, and carpets—manufacturers can assess the mop’s cleaning efficiency, durability, and effectiveness.

This technology helps manufacturers understand how factors like surface friction و mop material interact during use, leading to better designs and improvements in mop performance. By evaluating mop quality assurance data and using cleaning efficacy testers, manufacturers gain valuable insights into what makes a mop more efficient and durable for everyday cleaning tasks.

Conclusion

محاكاة استخدام الممسحة is a crucial component in the development and quality control of cleaning products. By utilizing advanced tools like cleaning efficacy testers and conducting thorough اختبار ضمان جودة الممسحة, manufacturers can ensure that their products meet the highest standards of performance, durability, and user satisfaction. These tests simulate real-world conditions, providing valuable data that helps improve the design and materials used in mops, leading to better cleaning results for consumers.

For manufacturers looking to optimize their mop products, the Cell Instruments cleaning efficacy tester is an excellent tool to ensure thorough and accurate testing. By integrating mop lab quality control processes, manufacturers can guarantee that their mops perform efficiently and consistently, meeting consumer expectations and enhancing cleaning experiences.